FDA MESHED FOOD GRADE PVC METAL HOSE

ONLINE CATALOGUE › HOSES › Water intake hoses

Plasticized PVC pipe with two layers and built-in galvanized steel spiral

Polyester fiber reinforcement, for the suction and passage of food liquids.

EU.according to DDC (see below)

FDA: according to DDC (see below)

free from Ortho Phthalates

Operating temperature from -5°C to +65°C. Maximum depression 9mH 2 O

APPLICATIONS:

Chemical plants, automatic cleaning systems, pneumatic equipment, level indicators, transfer of acids, salts, bases, transport of aggressive chemicals, compressed air, food industry.

All technical data refers to a temperature of 23°C ± 2°C (ISO 291). - Tolerances on all data indicated ± 5%.

EU CERTIFICATION

they are suitable for contact with aqueous, acidic and alcoholic foods (up to 20%) for which simulants A, B, and C are provided for repeated contact of a maximum of 30 minutes at a maximum temperature of 40°C.

The tubes are devices suitable for the passage of fluids or solids and therefore should not be used for storing food products. Avoid contact of food with the ends and the external surface of the tube.

Sterilization of the tubes must be performed before use at the user's expense.

The pipes are made of two-layer plasticized PVC with an embedded galvanized steel spiral and polyester fiber reinforcement. Smooth internal and external surfaces.

THE ABOVE PIPES COMPLY with the following European legislation:

- Directive 1978/142/EEC; Regulation 1935/2004/EC;

- Regulation 1895/2005/EC (epoxy derivatives);

- Regulation 2023/2006/EC (GMP);

- Regulation 10/2011/EU and subsequent amendments

and to the following Italian legislation:

- Ministerial Decree 03/21/1973 and subsequent updates and amendments

- Decree of the President of the Republic no. 777 of 23/08/1982 and subsequent updates and amendments

The above-mentioned tubes were manufactured exclusively with substances (monomers, pigments, and additives) listed in the positive lists of the aforementioned legislation. The material contains substances subject to restrictions in the aforementioned legislation and are listed below:

(*) Annex II EU Regulation 10/2011.

Test conditions

Simulant B: 3% acetic acid in aqueous solution Time and Temperature: 30 min at 40°C (repeated use)

Simulant C: 20% ethanol in aqueous solution Time and Temperature: 30 min at 40°C (repeated use)

The global migration tests of the various simulants were carried out under the conditions indicated in Annex V, Table 3, Test OM0

The analytical tests were conducted in accordance with Regulation 1935/2004/EC, Regulation 10/2011/EU, and Ministerial Decree 21/03/1973 on the liquid resulting from contact with a representative sample in “Article Filling” mode (for filling) with a maximum contact surface/volume ratio of 2.10 (dm2/dl) (simulant B, C) respecting the test conditions mentioned above. To verify compliance with the regulations, the calculations were performed assuming that 1 kg of food comes into contact with 6 dm2 of material.

According to experimental data and/or theoretical calculations, these substances comply with the provisions of Article 11 of Regulation 10/2011/EU, paragraph 3, letters a and b, and of the Ministerial Decree of March 21, 1973.

The overall migration limit, together with the other restrictions (metals, primary aromatic amines Reg. 10/2011/EU Annex II point 1,2) and the substances indicated above, comply with the limits of the same legislation including the update Reg. 1245/2020/EU.

In accordance with our suppliers' declarations regarding the raw materials used in the current formulation of the above-mentioned tubes, substances defined as "Biocides" (Regulation 528/2012/EU and subsequent amendments) are not intentionally added during tube production. Dual-use additives.

The tubes contain the following substances regulated by Regulation 1333/2008/EC (food additives) and subsequent amendments and by Regulation 1334/2008/EC (flavourings) and subsequent amendments: E 470a Sodium, Potassium and Calcium Salts of Fatty Acids; E 570 Fatty Acids.

The information stated refers only to suitability for contact with foodstuffs with the limitations indicated above.

This statement will be updated in the event of changes to the wording and/or if legislative references are modified and updated in a way that requires a new verification for compliance purposes.

FDA CERTIFICATION

it is declared that:

? the additives added in the formulation of the plasticized PVC mixture, constituting the pipes in question, fall, as of the latest amendment, among those indicated by FDA sub part 21 CFR, for the production of articles intended to come into contact with food: types I, II, IV-B, VI-A, VI-B, VI-C (up to 15 percent alcohol by volume), VII-B, and VIII described in 176.170 (c) of chapter 177.1210 table 1 and in the conditions of use from A to H described in 176.170 (c) of chapter 177.1210 table 2.

? PVC resin falls under FDA CFR part 21 Sec. 170.3 (l) “Prior sanction”.

The tubes are devices suitable for the passage of fluids or solids and therefore should not be used for food storage. Avoid contact of food with the ends and external surface of the tube. Sterilization of the tubes must be performed before use at the user's expense.

The above-mentioned articles have been manufactured exclusively with substances (monomers, pigments and additives) indicated in the positive lists of the aforementioned legislation.

The information declared refers only to suitability for contact with foodstuffs with the limitations indicated above.

This statement will be updated in the event of changes to the wording and/or if legislative references are modified and updated in a way that requires a new verification for compliance purposes.

Polyester fiber reinforcement, for the suction and passage of food liquids.

SMOOTH INTERNAL AND EXTERNAL SURFACES

EXTREME FLEXIBILITY (SEE CURVATURE RADIUS)

ABRASION RESISTANCE ISO 4649:3

TEMPERATURE OF USE -5°C +65°C

CRUSH RESISTANCE

EU.according to DDC (see below)

FDA: according to DDC (see below)

free from Ortho Phthalates

Operating temperature from -5°C to +65°C. Maximum depression 9mH 2 O

APPLICATIONS:

Chemical plants, automatic cleaning systems, pneumatic equipment, level indicators, transfer of acids, salts, bases, transport of aggressive chemicals, compressed air, food industry.

| Diameter internal mm | Diameter external mm | Pressure of exercise bar | Pressure of explosion bar | Radius of curvature mm | Weight m/g | Roll m |

| 19 | 28.0 | 20 | 60 | 80 | 450 | 60 |

| 25 | 35.5 | 20 | 60 | 90 | 670 | 60 |

| 30 | 40.5 | 16 | 48 | 105 | 770 | 60 |

| 32 | 42.5 | 16 | 48 | 110 | 800 | 60 |

| 35 | 47.0 | 14 | 42 | 125 | 1100 | 60 |

| 38 | 51.0 | 14 | 42 | 135 | 1150 | 30 |

| 40 | 53.5 | 14 | 42 | 140 | 1200 | 30 |

| 45 | 58.0 | 14 | 42 | 155 | 1400 | 30 |

| 50 | 63.5 | 14 | 42 | 170 | 1600 | 30 |

| 60 | 74.0 | 12 | 36 | 200 | 1980 | 30 |

| 63 | 77.0 | 12 | 36 | 210 | 2050 | 30 |

| 76 | 92.0 | 12 | 36 | 250 | 2800 | 30 |

| 80 | 96.0 | 10 | 30 | 300 | 2850 | 30 |

| 90 | 106.5 | 10 | 30 | 350 | 3300 | 30 |

| 102 | 119.0 | 10 | 30 | 400 | 3900 | 30 |

| 120 | 138.0 | 8 | 24 | 480 | 4800 | 20 |

| 127 | 145.0 | 7 | 21 | 500 | 5200 | 20 |

| 152 | 171.0 | 5 | 15 | 600 | 6700 | 20 |

EU CERTIFICATION

they are suitable for contact with aqueous, acidic and alcoholic foods (up to 20%) for which simulants A, B, and C are provided for repeated contact of a maximum of 30 minutes at a maximum temperature of 40°C.

The tubes are devices suitable for the passage of fluids or solids and therefore should not be used for storing food products. Avoid contact of food with the ends and the external surface of the tube.

Sterilization of the tubes must be performed before use at the user's expense.

The pipes are made of two-layer plasticized PVC with an embedded galvanized steel spiral and polyester fiber reinforcement. Smooth internal and external surfaces.

THE ABOVE PIPES COMPLY with the following European legislation:

- Directive 1978/142/EEC; Regulation 1935/2004/EC;

- Regulation 1895/2005/EC (epoxy derivatives);

- Regulation 2023/2006/EC (GMP);

- Regulation 10/2011/EU and subsequent amendments

and to the following Italian legislation:

- Ministerial Decree 03/21/1973 and subsequent updates and amendments

- Decree of the President of the Republic no. 777 of 23/08/1982 and subsequent updates and amendments

The above-mentioned tubes were manufactured exclusively with substances (monomers, pigments, and additives) listed in the positive lists of the aforementioned legislation. The material contains substances subject to restrictions in the aforementioned legislation and are listed below:

| NAME | Reference | Case no. | SML (mg/kg) |

| Stearic Acid | 24550 89040 | 57-11-4 | 60 |

| Vinyl Chloride | 26050 | 75-01-4 | 0.01 |

| 3-(3,5-di-tert-butyl-4-hydroxyphenyl) octadecyl propionate | 68320 | 2082-79-3 | 6 |

| Epoxidized Soybean Oil | 88640 | 8013-07-8 | 60 |

| Terephthalic acid, bis(2-ethylhexyl) ester | 92200 | 6422-86-2 | 60 |

| Zinc Salts | (*) | --- | 5 |

(*) Annex II EU Regulation 10/2011.

Test conditions

Simulant B: 3% acetic acid in aqueous solution Time and Temperature: 30 min at 40°C (repeated use)

Simulant C: 20% ethanol in aqueous solution Time and Temperature: 30 min at 40°C (repeated use)

The global migration tests of the various simulants were carried out under the conditions indicated in Annex V, Table 3, Test OM0

The analytical tests were conducted in accordance with Regulation 1935/2004/EC, Regulation 10/2011/EU, and Ministerial Decree 21/03/1973 on the liquid resulting from contact with a representative sample in “Article Filling” mode (for filling) with a maximum contact surface/volume ratio of 2.10 (dm2/dl) (simulant B, C) respecting the test conditions mentioned above. To verify compliance with the regulations, the calculations were performed assuming that 1 kg of food comes into contact with 6 dm2 of material.

According to experimental data and/or theoretical calculations, these substances comply with the provisions of Article 11 of Regulation 10/2011/EU, paragraph 3, letters a and b, and of the Ministerial Decree of March 21, 1973.

The overall migration limit, together with the other restrictions (metals, primary aromatic amines Reg. 10/2011/EU Annex II point 1,2) and the substances indicated above, comply with the limits of the same legislation including the update Reg. 1245/2020/EU.

In accordance with our suppliers' declarations regarding the raw materials used in the current formulation of the above-mentioned tubes, substances defined as "Biocides" (Regulation 528/2012/EU and subsequent amendments) are not intentionally added during tube production. Dual-use additives.

The tubes contain the following substances regulated by Regulation 1333/2008/EC (food additives) and subsequent amendments and by Regulation 1334/2008/EC (flavourings) and subsequent amendments: E 470a Sodium, Potassium and Calcium Salts of Fatty Acids; E 570 Fatty Acids.

The information stated refers only to suitability for contact with foodstuffs with the limitations indicated above.

This statement will be updated in the event of changes to the wording and/or if legislative references are modified and updated in a way that requires a new verification for compliance purposes.

FDA CERTIFICATION

it is declared that:

? the additives added in the formulation of the plasticized PVC mixture, constituting the pipes in question, fall, as of the latest amendment, among those indicated by FDA sub part 21 CFR, for the production of articles intended to come into contact with food: types I, II, IV-B, VI-A, VI-B, VI-C (up to 15 percent alcohol by volume), VII-B, and VIII described in 176.170 (c) of chapter 177.1210 table 1 and in the conditions of use from A to H described in 176.170 (c) of chapter 177.1210 table 2.

? PVC resin falls under FDA CFR part 21 Sec. 170.3 (l) “Prior sanction”.

The tubes are devices suitable for the passage of fluids or solids and therefore should not be used for food storage. Avoid contact of food with the ends and external surface of the tube. Sterilization of the tubes must be performed before use at the user's expense.

The above-mentioned articles have been manufactured exclusively with substances (monomers, pigments and additives) indicated in the positive lists of the aforementioned legislation.

The information declared refers only to suitability for contact with foodstuffs with the limitations indicated above.

This statement will be updated in the event of changes to the wording and/or if legislative references are modified and updated in a way that requires a new verification for compliance purposes.

Related products

CAMLOCK TYPE C

This type of fitting has been designed for the rapid and safe connection between two pipes in the shortest possible time...

CAMLOCK TYPE E

This type of fitting has been designed for the quick and safe co

AISI316 MALE HOSE PORT

Standard version metric hose connector with bsp male thread in aisi316 conical on request version with barbed tube with ...

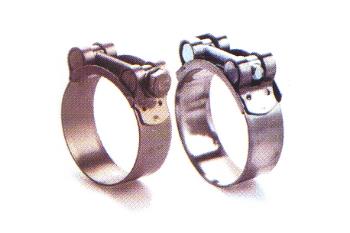

HEAVY DUTY BOLT CLAMP W2

Bolt collars for high pressures and for reinforced pipes, with spirals or with high hardness. the bolt engages directly ...

SAFETY CLAMP EN 14420 ALUMINUM

"spannloc" type safety clamp compliant with en 14420-3 in aluminum - steel screws maximum working pressure: 25...

CAMLOCK TYPE E MALE EN14420-7 (DIN)

This type of fitting is designed for the quick and safe joining of two pipes in the shortest possible time. by inserting...